- English

- русский

- العربية

- tiếng Việt

- Türkçe

- Deutsch

- 日本語

- 한국어

- ภาษาไทย

- Indonesia

- שפה עברית

- Português

- Español

- Français

- Italiano

- Nederlands

- Polski

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Gaeilge

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Exploring the Top 5 Innovative Automotive Sensors Revolutionizing Global Supply Chains

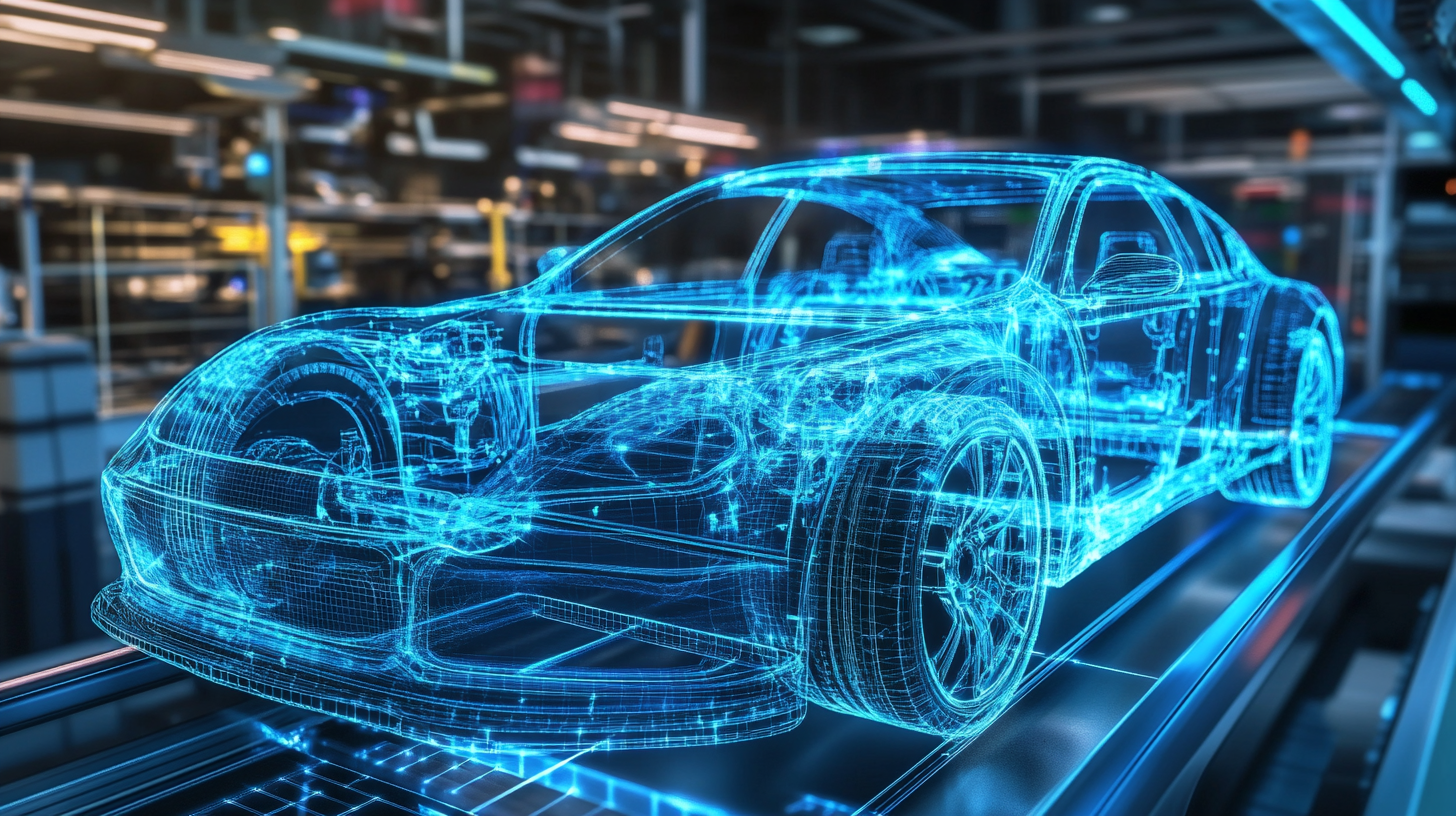

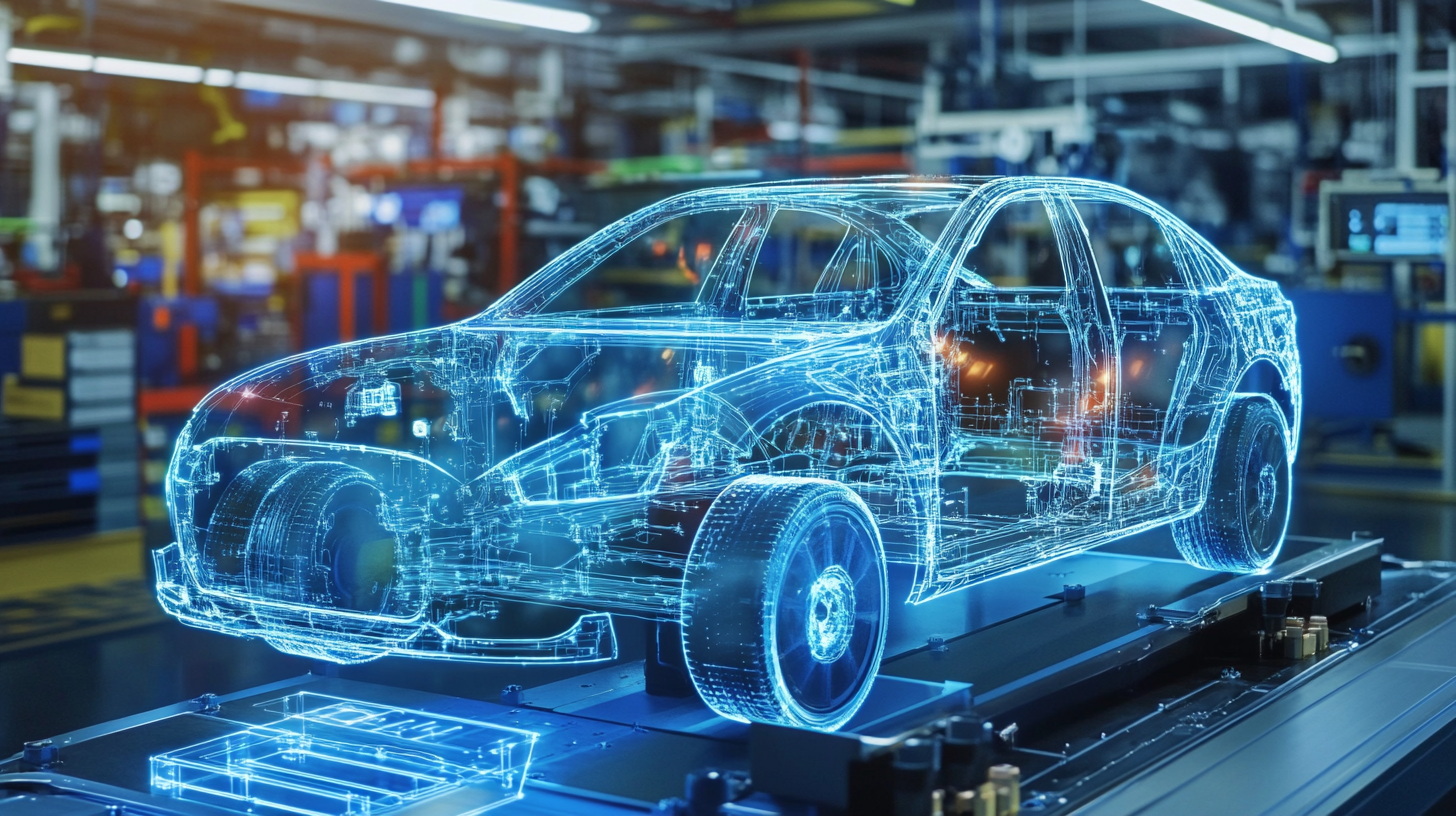

In the rapidly evolving automotive industry, the role of Automotive Sensors has become increasingly critical in redefining global supply chains. As we approach 2025, emerging technologies are paving the way for smarter, more efficient logistics and manufacturing processes. This blog explores the top five innovative Automotive Sensors that are not only enhancing vehicle performance but also streamlining supply chain operations across the globe.

By examining these advanced sensors, we will highlight their impactful contributions to real-time data monitoring, predictive maintenance, and overall operational efficiency, ultimately driving a technological revolution in automotive logistics. Join us as we delve into the future of supply chains shaped by these groundbreaking innovations.

The Role of IoT in Enhancing Automotive Sensor Efficiency

The automotive industry is undergoing a transformative shift, driven significantly by the integration of the Internet of Things (IoT) into innovative sensor technologies. Sensors, which can monitor everything from tire pressure to engine performance, are becoming increasingly sophisticated. According to a report by McKinsey, IoT-enabled sensors can lead to a 30% increase in operational efficiency, helping automotive manufacturers streamline supply chains and reduce costs. By facilitating real-time data exchange, these sensors ensure enhanced product quality and minimize downtime during production.

To better harness these advantages, automotive companies must focus on the seamless integration of IoT technology with their existing supply chain processes. This can involve using cloud-based platforms to collect and analyze sensor data, providing insights that facilitate predictive maintenance and foster agile decision-making. Companies that adopt such strategies reported a 25% decrease in supply chain disruptions, showcasing the direct impact of IoT on operational effectiveness.

**Tips for Implementation:**

1. Start with a pilot project that integrates IoT sensors in specific areas of the supply chain, allowing for manageable testing and adjustments.

2. Invest in training for staff on how to interpret sensor data and leverage it for performance improvements.

3. Regularly assess the effectiveness of the IoT integration and make necessary iterations to optimize both sensor deployment and data utilization.

Exploring the Top 5 Innovative Automotive Sensors Revolutionizing Global Supply Chains - The Role of IoT in Enhancing Automotive Sensor Efficiency

| Sensor Type | Key Features | IoT Integration | Impact on Supply Chain |

|---|---|---|---|

| LiDAR Sensors | High-resolution mapping, real-time obstacle detection | Real-time data transmission via cloud | Enhances delivery route optimization |

| Temperature Sensors | Critical temperature monitoring for sensitive components | Remote monitoring and alert systems | Maintains product integrity during transport |

| Pressure Sensors | Accurate pressure readings for tire and system monitoring | Data analytics for predictive maintenance | Reduces downtime through proactive checks |

| Ultrasonic Sensors | Proximity detection, obstacle avoidance | Integrates with navigation systems | Streamlines logistics and warehouse management |

| Accelerometers | Measures rate of acceleration and deceleration | Data collected for fleet management | Improves asset tracking and utilization |

Revolutionary LiDAR Technologies Transforming Supply Chain Logistics

The integration of revolutionary LiDAR technologies into the automotive sector is set to reshape supply chain logistics significantly. LiDAR, or Light Detection and Ranging, utilizes laser pulses to measure distances and generate precise 3D maps of the environment. In the context of supply chain management, this capability enhances the accuracy of vehicle navigation systems, ensuring safer and more efficient transportation of goods. With the ability to detect obstacles in real-time, LiDAR-equipped vehicles can drastically reduce delays and improve route optimization, leading to timely deliveries and cost savings.

Moreover, the application of LiDAR extends beyond navigation; it also plays a crucial role in warehouse management and inventory control. By scanning and mapping warehouse layouts, LiDAR systems facilitate better spatial management, allowing companies to optimize storage solutions and enhance the picking and packing processes. This technology not only streamlines operations but also minimizes human error, creating a more reliable logistics process. As these innovative sensors continue to evolve, they will undoubtedly drive advancements in efficiency and safety across global supply chains, proving essential for businesses aiming to stay competitive in a rapidly changing market.

Advancements in Radar Sensors: Impact on Vehicle Safety and Tracking

The automotive industry is undergoing a transformation with the advent of advanced radar sensors, significantly impacting vehicle safety and supply chain efficiency. These sensors utilize radio waves to detect objects around the vehicle, contributing to enhanced safety features like adaptive cruise control, collision avoidance systems, and emergency braking. With their ability to operate in various weather conditions and provide real-time data, radar sensors are pivotal in minimizing accidents and improving overall road safety.

In terms of supply chain logistics, radar technology allows for precise vehicle tracking and management. Fleet operators can monitor their vehicles’ locations and conditions in real-time, facilitating better route planning and reducing delivery times. The integration of radar sensors into supply chains not only streamlines operations but also optimizes resource allocation, leading to cost savings and increased productivity. As innovation continues to propel the capabilities of radar sensors, their role in enhancing vehicle safety and reshaping supply chains becomes ever more crucial, promising a future where technology and safety go hand in hand.

Utilizing Smart Cameras for Real-Time Data in Supply Chain Management

In the rapidly evolving landscape of supply chain management, smart cameras are emerging as pivotal tools for real-time data collection and operational efficiency. By leveraging AI-powered camera systems, businesses can enhance material handling visibility within warehouses significantly. These smart cameras integrate seamlessly with existing material handling equipment, providing insights that drive productivity and streamline operations.

To fully harness the potential of these technologies, companies can employ several strategies. First, implementing IoT technologies is crucial for optimizing supply chain visibility; it allows for real-time tracking and monitoring, which can vastly improve operational efficiency. Second, investing in AI-driven solutions can help businesses better manage supply chain activities, from monitoring product quality to balancing inventory levels. Finally, fostering collaboration between technology providers and manufacturers can further enhance the benefits of automation, leading to smarter decision-making processes.

As industries increasingly adopt these innovative sensors, the impact on logistical operations is profound. The integration of AI in transportation and manufacturing not only boosts productivity but also ensures safer and more efficient processes, paving the way for a smarter future in supply chain management.

Top 5 Innovative Automotive Sensors Impact on Supply Chain Efficiency

The Future of Automotive Sensors: Trends Shaping Global Supply Chains

The future of automotive sensors is poised to significantly reshape global supply chains as technological advancements continue to drive efficiency and innovation. One of the primary trends is the integration of Internet of Things (IoT) technology into sensor systems. These interconnected sensors provide real-time data on vehicle conditions, location, and performance. This capability allows manufacturers and suppliers to track components throughout the supply chain, reducing delays and minimizing waste. The ability to monitor vehicles in real time leads to proactive maintenance and streamlined logistics, ensuring the right parts are available at the right time.

The future of automotive sensors is poised to significantly reshape global supply chains as technological advancements continue to drive efficiency and innovation. One of the primary trends is the integration of Internet of Things (IoT) technology into sensor systems. These interconnected sensors provide real-time data on vehicle conditions, location, and performance. This capability allows manufacturers and suppliers to track components throughout the supply chain, reducing delays and minimizing waste. The ability to monitor vehicles in real time leads to proactive maintenance and streamlined logistics, ensuring the right parts are available at the right time.

Another trend is the rise of artificial intelligence (AI) in processing sensor data. AI algorithms can analyze vast amounts of information collected by automotive sensors, enabling manufacturers to predict potential failures before they occur. This predictive maintenance approach not only enhances vehicle reliability but also optimizes inventory management across the supply chain. By anticipating issues and improving demand forecasting, AI helps reduce costs and improve overall responsiveness to market changes. As these innovative automotive sensors evolve, they are set to revolutionize supply chain dynamics, making operations smarter and more resilient in an increasingly complex global market.