14 Toro Road Toronto, Ontario

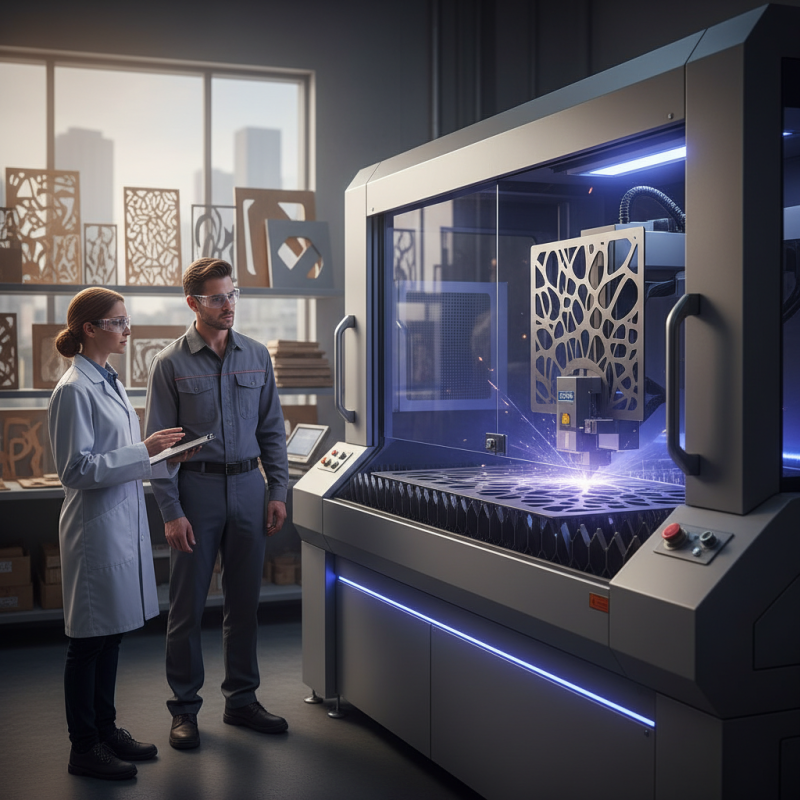

How to Choose the Best Laser Cutting Machine for Your Needs?

Choosing the right laser cutting machine can be daunting. Industry expert Dr. Emily Grant states, "The right machine can transform your workflow." With numerous options available, understanding your specific needs is vital.

laser cutting machines offer precision and efficiency. They can cut various materials, from metal to wood. However, not every machine suits every application. Some machines excel in speed, while others focus on detail. Your choice impacts productivity and quality.

Consider your projects carefully. Are you making intricate designs or large cuts? Reflect on your budget and future needs. Finding the best laser cutting machine is more than a simple decision; it requires thoughtful consideration of various factors.

Understanding Your Cutting Needs and Applications

Choosing the right laser cutting machine requires careful consideration of your specific cutting needs. Think about the materials you will work with. Different lasers are better suited for various substances like wood, metal, or acrylic. Each type of material has unique properties that affect how it reacts to laser cutting.

Consider the thickness of the materials you intend to cut. A machine's power level and cutting speed play a pivotal role here. Ensure you know the maximum thickness your project requires. If you're unsure, it might be worth experimenting to find the right fit.

Applications also matter. Are you creating intricate designs or simple shapes? This will influence your choice. Complex designs may need a more advanced machine. Limited budgets can lead to compromises. Reflect on what's essential for your projects. It's a balancing act between need and budget. Understanding these aspects will help you make a more informed choice.

Evaluating Different Types of Laser Cutting Machines

When evaluating different types of laser cutting machines, one must consider various factors. Fiber lasers, for instance, are known for their efficiency. According to industry reports, they can cut metal with greater precision than CO2 lasers. Fiber lasers use a solid-state laser source, which often leads to lower operational costs. This technology is gaining traction in many sectors.

CO2 lasers, on the other hand, offer versatility in cutting different materials. While they might not match the speed of fiber lasers for metals, they excel in cutting non-metal materials. They can process wood, acrylic, and textiles effectively. Some studies indicate that approximately 70% of businesses find CO2 lasers suitable for diverse applications.

However, selecting the right laser cutter isn't straightforward. Each type has its own strengths and weaknesses. For instance, fiber lasers often require more upfront investment. This can be a barrier for small businesses. On the other hand, CO2 lasers may need frequent maintenance and adjustments, which can lead to downtime. Understanding these nuances is critical for making an informed choice.

Key Features to Consider in a Laser Cutting Machine

When choosing a laser cutting machine, consider the power output. Higher power allows for cutting thicker materials. A 100-watt machine can cut through steel, but might be overkill for paper. Evaluate your typical projects. What materials will you work with most?

Next, think about the bed size. A larger bed enables bigger projects, but it may also increase costs. Machines with a 4x8 foot bed offer flexibility for larger pieces, while smaller beds are good for detailed work. Reflect on your workspace too. This can limit your options.

Finally, consider the software compatibility. Not all machines support the same software. Research what meets your design needs. This can lead to frustration if not aligned. Take time to plan and choose wisely. Your investment will shape your projects ahead.

Key Features to Consider in a Laser Cutting Machine

Assessing Cost vs. Quality for Long-term Investment

Choosing a laser cutting machine involves weighing cost against quality. Prices can vary significantly. A lower-cost machine may save money upfront but could lead to higher maintenance costs later. It’s crucial to consider the materials you plan to cut. Some machines handle specific materials better than others. Quality machines often provide more precise cuts and faster speeds, which can save time and resources in the long run.

Investing in a more expensive machine might seem daunting. However, reliability and performance often justify the price difference. Many users find that cheaper models wear out quickly. They may require frequent repairs or replacements. This can lead to interruptions in work and increased costs over time. It's essential to assess your production needs realistically. Do you need high-speed operations, or is precision your main concern?

Think about where you want your business to be in a few years. A top-tier machine can support growth and expansion. Yet, it’s also vital to avoid overspending. Analyze your budget and determine what features matter most to your projects. Reflect on the long-term benefits versus short-term savings to make a more informed decision.

Researching Manufacturer Reputation and Support Services

When choosing a laser cutting machine, evaluating manufacturer reputation is crucial. A reputable manufacturer is often a sign of quality. You should start by looking for reviews online. Customer testimonials offer insight into real-world experiences. Pay attention to common praises or complaints. Repeat issues could indicate potential problems.

Support services are equally important. A responsive support team can make a big difference. Imagine a breakdown during a critical project. You want help at your fingertips. Check if the manufacturer offers training, manuals, and prompt customer service. These factors can save time and frustration.

Not all manufacturers communicate effectively. Some may take days to respond. This can be a red flag. A good reputation means they stand behind their products. Think carefully about your priorities. Choosing the right machine is more than just price; it’s about trust and reliability.