14 Toro Road Toronto, Ontario

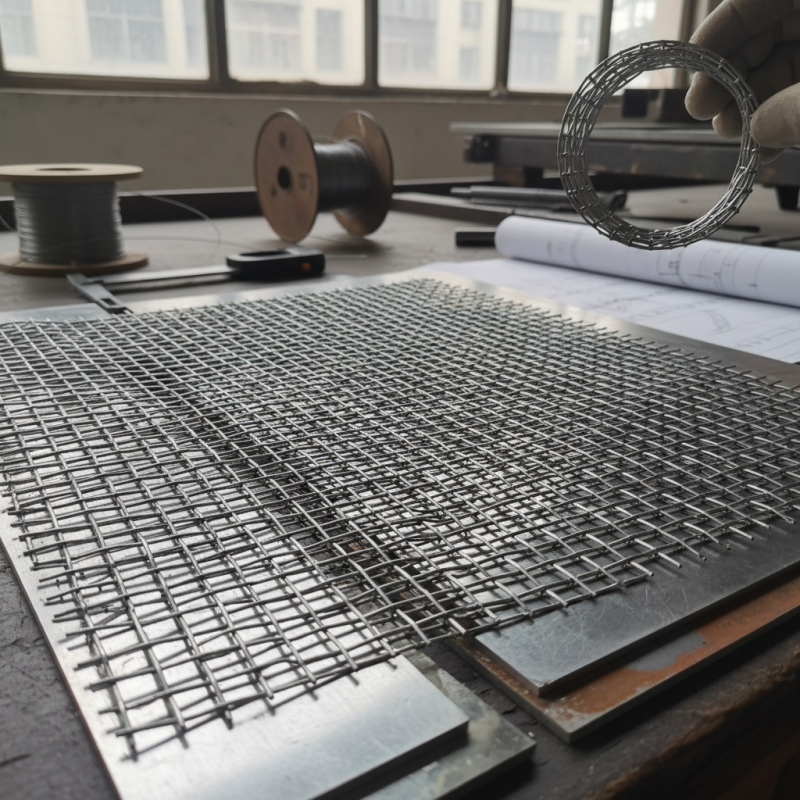

How to Choose the Best Stainless Steel Woven Wire Mesh?

Choosing the best stainless steel woven wire mesh can be challenging. Many factors influence the right choice, including intended use, mesh size, and wire diameter. This material is popular in various industries, from filtration to construction.

When evaluating stainless steel woven wire mesh, consider the environment in which it will be used. For example, high-corrosive areas require specific grades of stainless steel. Not every mesh suits every situation, and some may not perform as expected.

Additionally, quality is crucial. Low-quality meshes can lead to premature failures. Reflect on your specific needs; sometimes, investing more upfront saves costs in the long run. Not all suppliers are equal either; do thorough research before making a decision.

Factors to Consider When Choosing Stainless Steel Woven Wire Mesh

When choosing stainless steel woven wire mesh, certain factors can greatly influence your decision. One crucial aspect is the mesh size. A smaller mesh provides better filtration, while a larger mesh allows for greater airflow. The choice depends on your specific application. If you need to filter debris, a fine mesh is essential. However, if it's for structural support, a coarser mesh might be enough.

Another important consideration is the wire diameter. Thicker wires offer more strength and durability, but they can restrict flow or visibility. It's vital to balance these factors based on your project requirements. The material grade also plays a role in corrosion resistance. Not all stainless steel is created equal; some grades perform better in harsh environments.

Cost is another crucial element in your choice. Higher quality often comes with a higher price tag. It’s tempting to go for cheaper options, yet they might not last as long. Consider the long-term investment and potential replacement costs. Choosing the right stainless steel woven wire mesh requires careful thought, weighing both quality and price. It’s a classic case of wanting the best while navigating budget constraints.

Understanding Different Grates and Weaves in Stainless Steel Mesh

When selecting stainless steel woven wire mesh, understanding the different grates and weaves is crucial. Various weave patterns offer unique benefits. Plain weave is common and provides excellent support. Twill weave, with its diagonal pattern, enhances flexibility and strength.

Some applications require specific mesh sizes and openings. A tighter mesh blocks smaller particles. However, it can restrict airflow. Conversely, a looser weave allows for better ventilation but might not filter effectively.

Tips: Consider the intended use of the mesh first. Identify the particles you want to filter out. This choice impacts the weave required for optimal performance. Review the material's durability for your environment. A less robust mesh may falter under demanding conditions. Remember, compromises in strength for versatility could lead to future issues.

Evaluating the Corrosion Resistance of Stainless Steel Wire Mesh

When assessing the corrosion resistance of stainless steel woven wire mesh, one must consider various factors. The type of stainless steel used plays a crucial role. For instance, austenitic stainless steels, such as 304 or 316 grades, exhibit exceptional corrosion resistance. According to a study by the Corrosion Engineering Committee, 316 stainless steel offers around 50% more resistance to chloride-induced pitting than 304.

Environmental factors also come into play. Exposure to harsh chemicals, high humidity, or saline environments can accelerate corrosion. Data from the National Association of Corrosion Engineers suggests that even minor amounts of chlorides can cause significant damage over time. Understanding the environment in which the mesh will be used is essential for making an informed choice.

While stainless steel is known for its durability, not all applications benefit equally. Some industries face unique challenges, such as exposure to extreme temperatures or aggressive cleaning agents. In these cases, a standard stainless steel mesh may not be sufficient. Evaluating specific project needs can lead to better decisions. The wrong choice could result in premature failure, requiring costly replacements.

Determining the Appropriate Mesh Size for Your Application

Choosing the right mesh size for stainless steel woven wire mesh is crucial for optimal performance. Different applications require different mesh sizes. For instance, a mesh size of 0.5 mm is ideal for filtration in food processing, while 2 mm may be more suitable for architectural applications. According to industry reports, a mesh size that is too small may lead to clogging, while one that is too large reduces effectiveness.

When selecting mesh size, consider the material being filtered. For particles smaller than 1 mm, a tighter mesh is essential. However, a mesh size that exceeds the particle size can lead to inefficiency. In some instances, manufacturers suggest using a combination of mesh sizes for better results. This mixed approach can enhance filtration while reducing pressure loss.

Tips: Always test the mesh in real conditions. Visit suppliers to examine samples. Conducting a trial run can save time and resources later. Check that the selected mesh size meets industry safety standards. A well-chosen mesh contributes to product quality and safety. Revisit your choice periodically as needs may evolve. The importance of correct sizing cannot be overstated; misjudgments can result in costly errors.

Comparing Cost and Quality of Stainless Steel Wire Mesh Options

Choosing the best stainless steel woven wire mesh involves balancing cost and quality. Many options are available, each with unique properties. The price can vary widely based on materials, weave tightness, and thickness. High-quality meshes provide durability and resistance to corrosion. However, they often come at a higher price.

When considering options, think about your specific needs. If the mesh is for a temporary function, a lower-priced option may suffice. For permanent installations, investing in higher quality is wise. It can save money over time due to reduced replacements.

**Tip:** Always request samples before purchasing large quantities. This helps you assess the material's quality and suitability for your needs.

Another key consideration is the mesh's specifications. Dimensions, wire diameter, and opening size affect both price and performance. A finer mesh might be more expensive but can prevent smaller particles from passing through.

**Tip:** Calculate the total long-term costs, including maintenance and replacements. Sometimes, cheaper options lead to higher expenses later. Make informed choices to get the best value for your needs.

How to Choose the Best Stainless Steel Woven Wire Mesh?

| Mesh Type | Aperture Size (mm) | Wire Diameter (mm) | Material Grade | Cost ($/m²) | Typical Use |

|---|---|---|---|---|---|

| Plain Weave | 1.0 | 0.5 | 304 | 15 | Filtration |

| Twilled Weave | 2.0 | 0.8 | 316 | 18 | Industrial Applications |

| Reverse Dutch Weave | 0.5 | 0.3 | 430 | 20 | Sifting |

| Welded Wire Mesh | 3.0 | 1.0 | 304 | 25 | Construction |