14 Toro Road Toronto, Ontario

How to Adjust Your Saw Swing for Accurate Cuts?

In the world of woodworking, mastering the saw-swing technique is crucial for achieving precise cuts. Expert carpenter John Matthews once said, "The swing of the saw determines the quality of your work." His words resonate deeply with anyone striving for perfection in their craft.

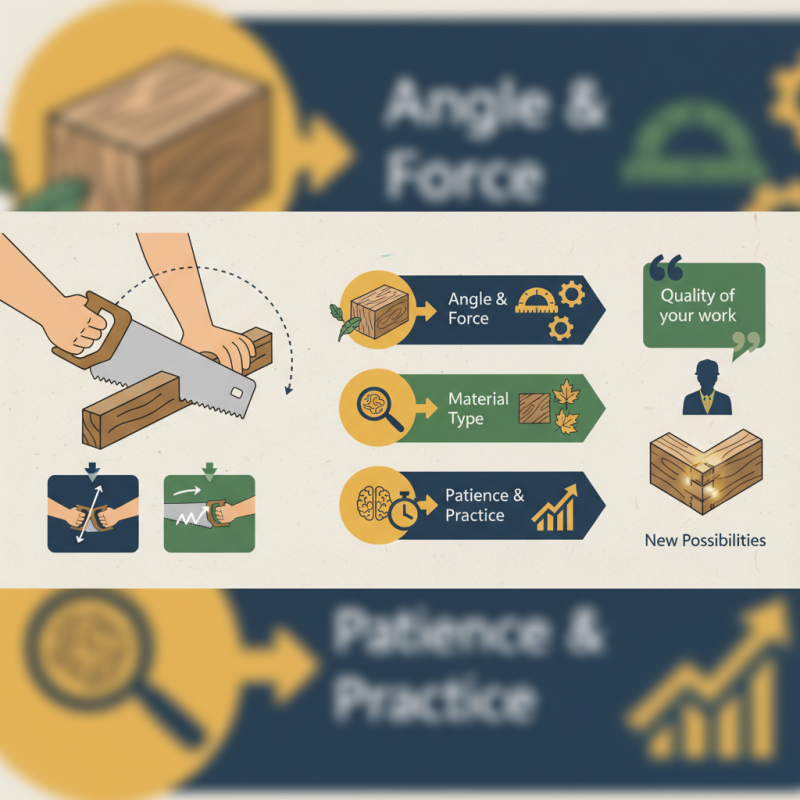

Adjusting your saw-swing can be the difference between success and frustration. Many new woodworkers struggle with this concept. The angle and force behind each swing play a key role. A miscalibrated saw-swing can lead to uneven edges and wasted materials. Understanding how to fine-tune your technique requires patience and practice.

Think about the last time you felt your cuts weren’t quite right. Perhaps your saw-swing was inconsistent. Reflecting on your approach can lead to improvements. Consider trying different swings for various materials. Each wood type reacts differently, often requiring adjustments. Fine-tuning your saw-swing opens new possibilities in your woodworking projects.

Understanding the Basics of Saw Swing Mechanics for Precision Cutting

Understanding saw swing mechanics is essential for precision cutting. The swing refers to the arc path made by the saw blade during a cut. When the angle is off, cuts can become uneven. The key is to maintain a consistent swing. This ensures the blade meets the material at the correct angle.

Many factors influence swing. For example, the speed at which you push the saw can affect the depth of cut. Using too much force might distort the swing. A gentle touch often leads to cleaner cuts. Consider your stance; an unsteady position can throw off your rhythm. Pay attention to body mechanics. It’s about finding that sweet spot between pressure and control.

Practicing will reveal flaws in your technique. You might find your cuts aren’t as straight as you hoped. Reflect on your approach. A slight adjustment in your grip could lead to better results. Remember, even small changes can have a big impact. Precision comes from consistent practice. Keep experimenting until the cuts become more accurate.

Common Issues Causing Inaccurate Cuts and How to Resolve Them

When achieving accurate cuts with your saw, several common issues can throw off your results. One prevalent problem is inadequate blade alignment. According to industry research, misalignment can lead to a staggering 15% increase in cutting variance. It’s essential to regularly check your blade against a straightedge. Even a minor deviation can create noticeable inaccuracies in your work.

Another concern is improper cutting technique. Many users tend to rush, which can result in uneven pressure on the saw. Studies indicate that maintaining consistent pressure improves overall cut quality and reduces errors. If your cuts exhibit chipping on one side, it may signal that you are applying uneven force. Pay attention to your posture as you saw; balance is key.

Lastly, blade selection plays a critical role. Using the wrong type of blade for your material can lead to poor cuts. For instance, hardwood requires a different tooth configuration than softwood. A survey found that 42% of professional craftsmen encountered issues due to inappropriate blades. Take the time to match your blade with the material, and your cutting accuracy will greatly improve.

Recommended Adjustments Based on Blade Types and Materials

When making accurate cuts, adjusting your saw swing based on blade types and materials is crucial. Different blades require unique settings. For instance, a fine-tooth blade is ideal for cutting plywood. It helps create smooth edges. However, it can stall if the swing is too aggressive. Moderate your swing to achieve cleaner results.

For hardwoods, a coarse-tooth blade works best. It absorbs more material per pass, but too much swing leads to splintering. Keeping your swing steady will prevent damaging the wood. You might notice that some cuts don’t meet your expectations. It’s essential to analyze your technique and make necessary changes.

Adjusting your swing also involves understanding materials. Softwoods respond differently than metals. If you’re cutting aluminum, a slower swing can produce accurate cuts. Yet, a too slow swing may lead to excess heat and warp the blade. Balance is critical. Learn from your experiences. Experiment and refine your approach for better results.

How to Adjust Your Saw Swing for Accurate Cuts?

| Blade Type | Material | Recommended Swing Adjustment | Notes |

|---|---|---|---|

| High-Speed Steel (HSS) | Wood | Minimize swing for finer cuts | Best for softwoods |

| Carbide-Tipped | Plywood | Moderate swing adjustment is optimal | Durable for repeated cuts |

| Diamond Bladed | Ceramic Tile | Minimal to none for precision | Avoid excessive pressure |

| Bi-Metal Blades | Plastic | Moderate swing for clean cuts | Good for various plastics |

| Wood Blades | Hardwood | Wider swing for thicker cuts | Ensure blade is sharp |

The Impact of Saw Swing Angle on Cut Quality and Safety

The angle of your saw swing plays a crucial role in the quality of your cuts. A precise swing angle leads to cleaner, smoother edges. When the swing is too wide or too narrow, it can compromise the cut. For example, a wide swing may cause tear-out on wood fibers. This can make adjustments necessary. Think about how often you overlook this detail.

Adjusting the swing isn’t just about precision. It also affects safety. A miscalibrated angle can lead to kickback, putting you at risk. Many users have experienced this moment of surprise. It’s essential to practice with different angles. What feels comfortable in your hand can be misleading. You might still need to alter your habits for better outcomes.

Try using a protractor or an angle finder. Measure where the blade meets the material. Pay attention to how small changes affect your results. Sometimes, it’s good to rethink your technique. A simple adjustment in swing angle could save material and reduce accidents. Each cut teaches you something new. Embrace these lessons for improvement.

Techniques for Fine-Tuning Your Saw Swing for Professional Results

Adjusting your saw swing is key to making precise cuts. Begin by standing steady. Grip the saw tightly yet comfortably. Focus on your body posture. Your feet should be shoulder-width apart. This position helps maintain balance.

Next, practice the swing. A slow start is vital. Quick movements can lead to mistakes. Watch your hand placement. The saw should glide smoothly along the material. If it veers off course, adjust your grip. Sometimes, repositioning your body can help.

Consider the angle of the cut. A subtle tilt can change everything. If the cut doesn’t look right, don’t rush. Reflect on your technique. Was your swing too wide? Did you apply enough pressure? Making adjustments can lead to significant improvements. It’s all about fine-tuning your approach for better outcomes.

How to Adjust Your Saw Swing for Accurate Cuts?

This chart shows the relationship between the saw swing angle adjustment and the accuracy of cuts, measured in millimeters of deviation from the intended cut line. The objective is to demonstrate how fine-tuning the swing can lead to improved cutting precision.